www.engineering-thailand.com

22

'10

Written on Modified on

CIAT has installed a cold storage system at the Valenciennes Hospital Centre, in the North of France.

The Cristopia cold storage system, commissioned a few months ago, optimizes the hospital’s energy consumption and uses refrigerating units of a 2200 kW combined power instead of the 4000 kW initially planned. This CIAT equipment produces the cooling capacity needed for the entire building (Jean BERNARD), over 110 000 m2, with a 1000 bed capacity, including, amongst other units, 14 operating theatres, 20 imaging rooms and 29 intensive care beds. The installation will pay for itself in only 4 years.

Within the framework of a 70 000 m2 project (including a 55 000 extension), the capacity of the Valenciennes Jean Bernard Hospital, in the North of France, has been increased to 1000 beds. CIAT equipment produces the cooling capacity for the entire building, both new and old parts, whether patient’s rooms or technical rooms which must be kept cool permanently (imaging, operating theatres, etc). The cold storage principle consists of saving and storing the cold when the need is low in the building, mainly during the night, taking advantage of the cooler outside temperature for the condenser. By smoothing cold production over 24 hours, the energy consumption costs are reduced and the equipment optimally sized.

“For us, the Cristopia system presents three major advantages. First of all, the installation is smaller. We needed a power of 4000 kW initially, but with Cristopia, 2200 kW is sufficient. Without the cold storage, 4000 kW equipment would have to be installed and therefore the electrical power contract subscribed and consumed power would double (and add an additional 15 to 30 tonne load on the roof). In addition, the Cristopia system uses electricity at low tariff rates. The cooling capacity is stored during the night, and delivered when the tariffs are high during the day. This therefore avoids very expensive consumption peaks.

Finally, in comparison with the classic tube exchanger storage systems, Cristopia requires no maintenance.

There is no chemical treatment, no need to completely empty the system regularly to maintain performance, and furthermore, moving the electricity consumption from during the day to night time has reduced the carbon footprint of the building” said Stephane BREBION, Project Manager of SODEG Engineering, who recommended this solution:

Three CIAT Powerciat, 2150 kW combined capacity units are installed on the roof of the main building, beside the helipad. The glycol primary circuit conveys the cold to 4 underground tanks, 45m3 each, containing the cold storage nodules. Then the secondary circuit distributes the energy to the sub-stations, which in turn supply the air treatment units and the terminal units. More than 100 CIAT COADIS2 type comfort units equip the hospital offices.

“The overall CIAT offer was important in our choice. Supply of both the Cristopia storage system as well as the cooling units and cold storage adjustment units is certainly an advantage. They could promise optimization of the system and of all results” Morad RAHAL, Hospital Centre Technical Director, told us.

With 25 years experience in thermal energy storage systems, the CIAT Group is today the world leader in the sector. They have installed more than 2500 systems, which saves more than 800 MW of electrical power daily through the CRISTOPIA equipment. A use range of –33°C to +27°C and an energy efficiency superior to other solutions on the market have largely contributed to this success. The CRISTOPIA system uses nodules, polyolefin spheres obtained by extrusion blow moulding. The nodules are filled with phase change material (solid-liquid). In addition to its remarkable thermal performance in terms of exchange power, the CRISTOPIA nodule has an exceptionally long service life (the equivalent of more than 30 years use under normal conditions).

Operating principle:

Storage alone: During the night, energy is stored using the refrigerating unit, which chills the cooling fluid. This fluid circulates at a temperature lower than the fusion temperature of the phase change material contained in the nodules, causing its crystallization.

Direct production: When the demand is less than the power of the refrigerating unit, cold is produced directly by the unit alone.

Delivery alone: The thermal energy storage system can be used alone without the refrigerating unit in operation (as a backup or at peak times).The coolant enters the system at a temperature above the fusion point of the phase change material and is cooled on contact with the nodules.

Direct production and delivery: When the demand is greater than the power of the refrigerating unit, needs are met by joint operation of the unit and the storage system.

Direct production and storage: In this operating mode (generally at night), the refrigerating unit charges the storage system and provides for the night time requirements (limited to 10 / 15 % of the unit power in charging mode).

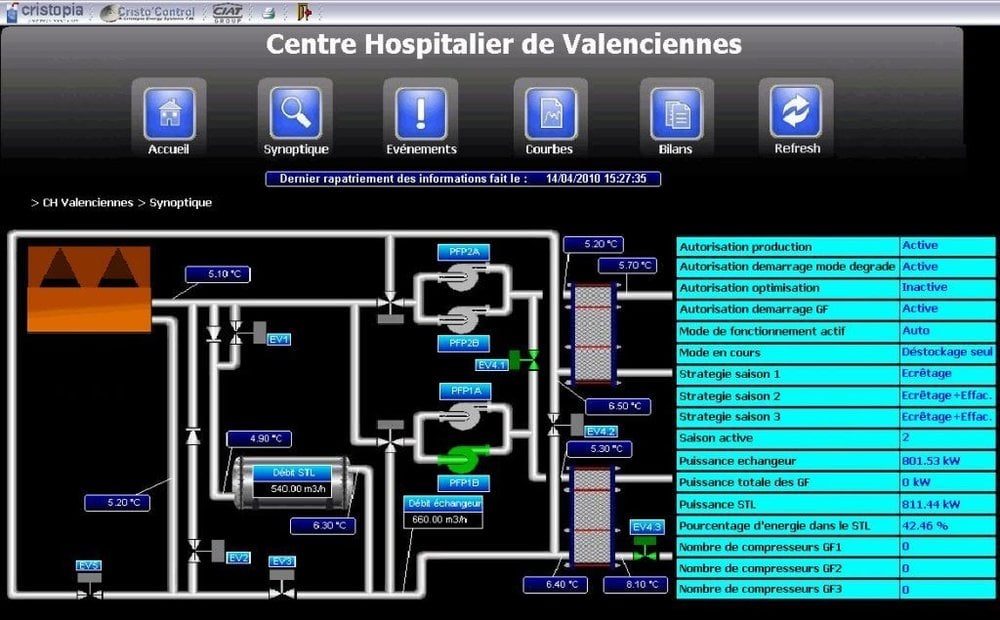

Cristo’Control

The Ciat Group has perfected a unique control system in its “Cristo’Control” range, intended to manage the refrigerating unit. “Cristo’Control” is mounted in a small electrical cabinet connected to the general power supply cabinet and measurement equipment. Cristo’Control, the smart part of the installation, manages all of the parameters to optimize the overall energy efficiency of the power unit throughout the year. According to the user’s strategic choices, charging rate, season, climatic conditions, electricity tariffs and installation events, Cristo’Control reacts dynamically with the aim of providing the most reliable service and achieve the best system performance. The installation is monitored locally (by a display panel on the Cristo’Control unit) or remotely (sending information to one or several remote stations). The information is sent to the maintenance company or any other organization the owner of the installation chooses. Remote control is through a series link or an ADSL line.

Remote monitoring on the site www.Cristo’Control.com analyzes operation of the installation in real time as well as over the medium and long term. Preventive maintenance is assisted by monitoring operating parameter drifts. The risks of curative work as well as operating costs are reduced, and the quality of service improved. Long term remote monitoring makes it possible to adapt control strategies according to changing requirements or new electricity tariffs.

Photo key:

VAL1.jpeg: PowerCiat refrigerating units on roof

VAL2.jpeg: Cristopia cold storage tanks

VAL7.jpeg: Supervision of the installation with Cristo’Control

“For us, the Cristopia system presents three major advantages. First of all, the installation is smaller. We needed a power of 4000 kW initially, but with Cristopia, 2200 kW is sufficient. Without the cold storage, 4000 kW equipment would have to be installed and therefore the electrical power contract subscribed and consumed power would double (and add an additional 15 to 30 tonne load on the roof). In addition, the Cristopia system uses electricity at low tariff rates. The cooling capacity is stored during the night, and delivered when the tariffs are high during the day. This therefore avoids very expensive consumption peaks.

Finally, in comparison with the classic tube exchanger storage systems, Cristopia requires no maintenance.

There is no chemical treatment, no need to completely empty the system regularly to maintain performance, and furthermore, moving the electricity consumption from during the day to night time has reduced the carbon footprint of the building” said Stephane BREBION, Project Manager of SODEG Engineering, who recommended this solution:

Three CIAT Powerciat, 2150 kW combined capacity units are installed on the roof of the main building, beside the helipad. The glycol primary circuit conveys the cold to 4 underground tanks, 45m3 each, containing the cold storage nodules. Then the secondary circuit distributes the energy to the sub-stations, which in turn supply the air treatment units and the terminal units. More than 100 CIAT COADIS2 type comfort units equip the hospital offices.

“The overall CIAT offer was important in our choice. Supply of both the Cristopia storage system as well as the cooling units and cold storage adjustment units is certainly an advantage. They could promise optimization of the system and of all results” Morad RAHAL, Hospital Centre Technical Director, told us.

With 25 years experience in thermal energy storage systems, the CIAT Group is today the world leader in the sector. They have installed more than 2500 systems, which saves more than 800 MW of electrical power daily through the CRISTOPIA equipment. A use range of –33°C to +27°C and an energy efficiency superior to other solutions on the market have largely contributed to this success. The CRISTOPIA system uses nodules, polyolefin spheres obtained by extrusion blow moulding. The nodules are filled with phase change material (solid-liquid). In addition to its remarkable thermal performance in terms of exchange power, the CRISTOPIA nodule has an exceptionally long service life (the equivalent of more than 30 years use under normal conditions).

Operating principle:

Storage alone: During the night, energy is stored using the refrigerating unit, which chills the cooling fluid. This fluid circulates at a temperature lower than the fusion temperature of the phase change material contained in the nodules, causing its crystallization.

Direct production: When the demand is less than the power of the refrigerating unit, cold is produced directly by the unit alone.

Delivery alone: The thermal energy storage system can be used alone without the refrigerating unit in operation (as a backup or at peak times).The coolant enters the system at a temperature above the fusion point of the phase change material and is cooled on contact with the nodules.

Direct production and delivery: When the demand is greater than the power of the refrigerating unit, needs are met by joint operation of the unit and the storage system.

Direct production and storage: In this operating mode (generally at night), the refrigerating unit charges the storage system and provides for the night time requirements (limited to 10 / 15 % of the unit power in charging mode).

Cristo’Control

The Ciat Group has perfected a unique control system in its “Cristo’Control” range, intended to manage the refrigerating unit. “Cristo’Control” is mounted in a small electrical cabinet connected to the general power supply cabinet and measurement equipment. Cristo’Control, the smart part of the installation, manages all of the parameters to optimize the overall energy efficiency of the power unit throughout the year. According to the user’s strategic choices, charging rate, season, climatic conditions, electricity tariffs and installation events, Cristo’Control reacts dynamically with the aim of providing the most reliable service and achieve the best system performance. The installation is monitored locally (by a display panel on the Cristo’Control unit) or remotely (sending information to one or several remote stations). The information is sent to the maintenance company or any other organization the owner of the installation chooses. Remote control is through a series link or an ADSL line.

Remote monitoring on the site www.Cristo’Control.com analyzes operation of the installation in real time as well as over the medium and long term. Preventive maintenance is assisted by monitoring operating parameter drifts. The risks of curative work as well as operating costs are reduced, and the quality of service improved. Long term remote monitoring makes it possible to adapt control strategies according to changing requirements or new electricity tariffs.

Photo key:

VAL1.jpeg: PowerCiat refrigerating units on roof

VAL2.jpeg: Cristopia cold storage tanks

VAL7.jpeg: Supervision of the installation with Cristo’Control