www.engineering-thailand.com

09

'10

Written on Modified on

Cleancon concept

The number of vehicle failures due to electronic components is increasing every year. Electronic components are involved in nearly half of all emergency assistance calls received by the German motorists’ association ADAC. Often coming from screws, microscopic contamination particles on interconnects regularly cause failures in control units. To solve this problem, Arnold Umformtechnik has developed the Cleancon concept.

Vehicle breakdowns due to electronic components occupy a prominent position in the statistics, accounting for a hefty 48.5% of all failures in 2008. In many cases these malfunctions are caused by microscopic particulate contamination on screws. As a result, components costing only a few cents are responsible for costs amounting to several hundred euros. Conventional cleaning processes are virtually ineffective or even counterproductive due to their negative effect on the mechanical properties of the fastening components.

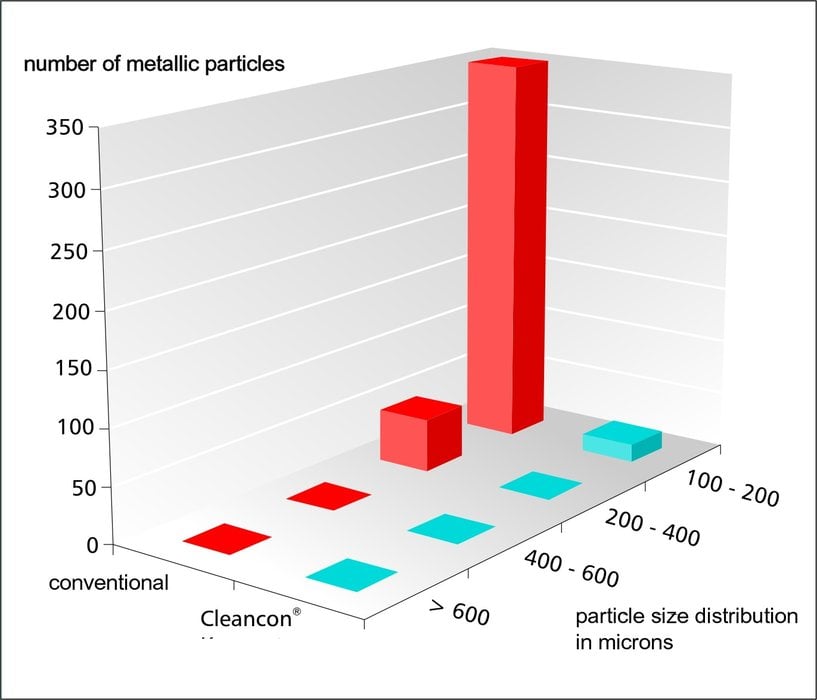

The Cleancon® concept developed by Arnold Umformtechnik creates a holistic solution and represents a milestone in avoiding vehicle failures due to electronic components. An innovative combination of the systematic coordination of all parameters affecting the cleanliness of components, cleanliness-oriented production, microcleaning and low-friction coating, and packaging of fastening components under cleanroom conditions allows substantially better cleanliness figures to be achieved .

Thanks to extensive investments in “engineering cleanliness”, Arnold Umformtechnik has succeeded in achieving a virtually unique level of cleanliness of their fastening components up to the time of installation by their customers, without thereby degrading the mechanical properties of the components. Furthermore, precise cleanliness figures can be documented at all times by analytic measurement methods in their in-house laboratory. This ensures that the process has a positive impact on the operation of the individual electronic components and thereby on the operational reliability of the entire vehicle.

The Cleancon® concept developed by Arnold Umformtechnik creates a holistic solution and represents a milestone in avoiding vehicle failures due to electronic components. An innovative combination of the systematic coordination of all parameters affecting the cleanliness of components, cleanliness-oriented production, microcleaning and low-friction coating, and packaging of fastening components under cleanroom conditions allows substantially better cleanliness figures to be achieved .

Thanks to extensive investments in “engineering cleanliness”, Arnold Umformtechnik has succeeded in achieving a virtually unique level of cleanliness of their fastening components up to the time of installation by their customers, without thereby degrading the mechanical properties of the components. Furthermore, precise cleanliness figures can be documented at all times by analytic measurement methods in their in-house laboratory. This ensures that the process has a positive impact on the operation of the individual electronic components and thereby on the operational reliability of the entire vehicle.