www.engineering-thailand.com

25

'08

Written on Modified on

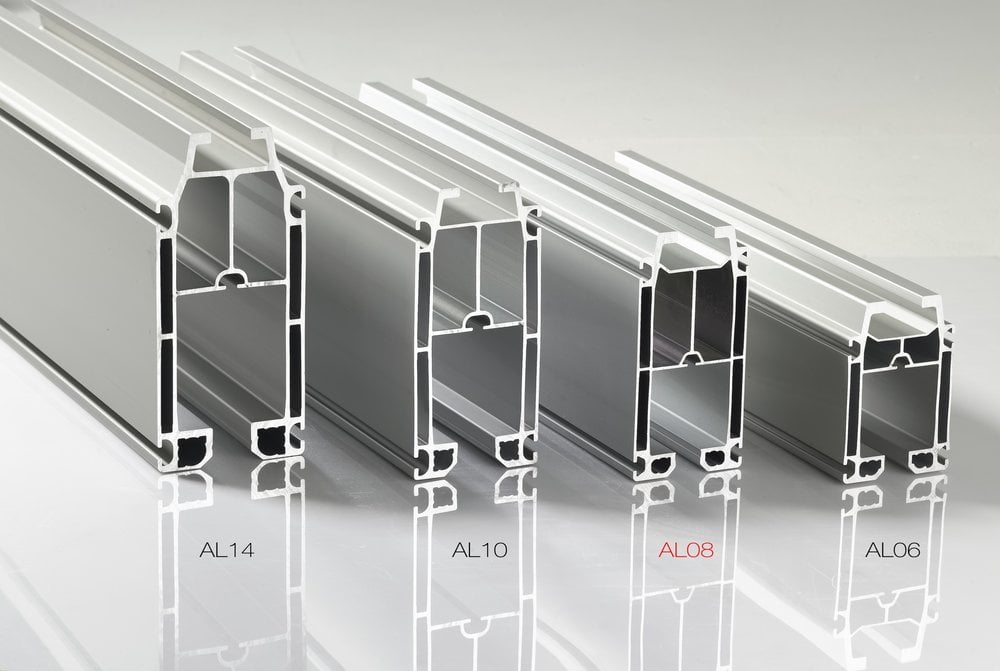

Extension of the EUROSYSTEM ALU range

VERLINDE is proposing a new hollow profile for its family of handling rails for stages in EUROSYSTEM ALU aluminium. Available in a black anodised version, and particularly specialised for the entertainment industry, this fourth profile, called AL08, is intended for loads up to 500 kg.

EUROSYSTEM ALU is intended for setting up tailor-made handling systems for stages for loads up to 2000 kg. The AL08 profile will be the meeting point between the AL06 and the AL10 (which goes up to 2000 Kg).

4 sizes of profiles:

-AL06, 6.5 kg/m, up to 320 kg

-AL08, 8.6 kg/m, up to 500 kg

-AL10, 10.6 kg/m, up to 2000 kg

-AL14, 14.5 kg/m, up to 2000 kg

EUROSYSTEM ALU stands out by its ease of assembly. First of all, the lightness of the hollow aluminium profiles makes them easy to position and handle for assembly. They can all be moved and positioned manually without any specific hoisting equipment. The elements are attached to each other, and the system to the load-bearing structure, by means of simple bolting and do not require any special tools. The external groves on the profiles are then compatible with the ITEM standardised attachment system. The profiles are then manufactured by extrusion which gives them substantial geometric homogeneity and can be assembled without any mechanical adjustment being necessary.

Thanks to VERLINDE's EUROSYSTEM ALU, the full handling system in hollow aluminium profiles is 50% lighter than a traditional steel structure. In the case of new buildings, renovations or extensions, regardless of whether it concerns a multipurpose entertainment building or a theatre, substantial savings are thus achieved on the load-bearing structure, the dimensions of which could be calculated to the minimum according to this equipment.

4 sizes of profiles:

-AL06, 6.5 kg/m, up to 320 kg

-AL08, 8.6 kg/m, up to 500 kg

-AL10, 10.6 kg/m, up to 2000 kg

-AL14, 14.5 kg/m, up to 2000 kg

EUROSYSTEM ALU stands out by its ease of assembly. First of all, the lightness of the hollow aluminium profiles makes them easy to position and handle for assembly. They can all be moved and positioned manually without any specific hoisting equipment. The elements are attached to each other, and the system to the load-bearing structure, by means of simple bolting and do not require any special tools. The external groves on the profiles are then compatible with the ITEM standardised attachment system. The profiles are then manufactured by extrusion which gives them substantial geometric homogeneity and can be assembled without any mechanical adjustment being necessary.

Thanks to VERLINDE's EUROSYSTEM ALU, the full handling system in hollow aluminium profiles is 50% lighter than a traditional steel structure. In the case of new buildings, renovations or extensions, regardless of whether it concerns a multipurpose entertainment building or a theatre, substantial savings are thus achieved on the load-bearing structure, the dimensions of which could be calculated to the minimum according to this equipment.